Operational Effectiveness: IT Department of a leading Australian Wealth Management Company

This case study illustrates a typical scenario where the traditional Six Sigma DMAIC approach should be applied in combination with Lean tools like value stream mapping.

The project was implemented in the IT department of the Australian Wealth Management Company. The department provides IT services to various users across multiple business units. The environment is typical for IT service organisation in a financial services organisation:

- The IT department provided services for a large number of applications (in this case close to 400, most of them differing widely in their usage, administration and operation).

- Some of the applications had been developed internally, while others had been purchased ‘off-the-shelf’ from vendors with the vendors also being involved in providing support services.

- Various IT services had been outsourced to external service providers, which were coordinated and managed by the IT department

- Knowledge for most applications, both in terms of its specific functionality as well as its overall usage and administration, was often confined to individuals

- IT services to the business were not governed by service agreements and the performance of the process was not measured on an ongoing basis

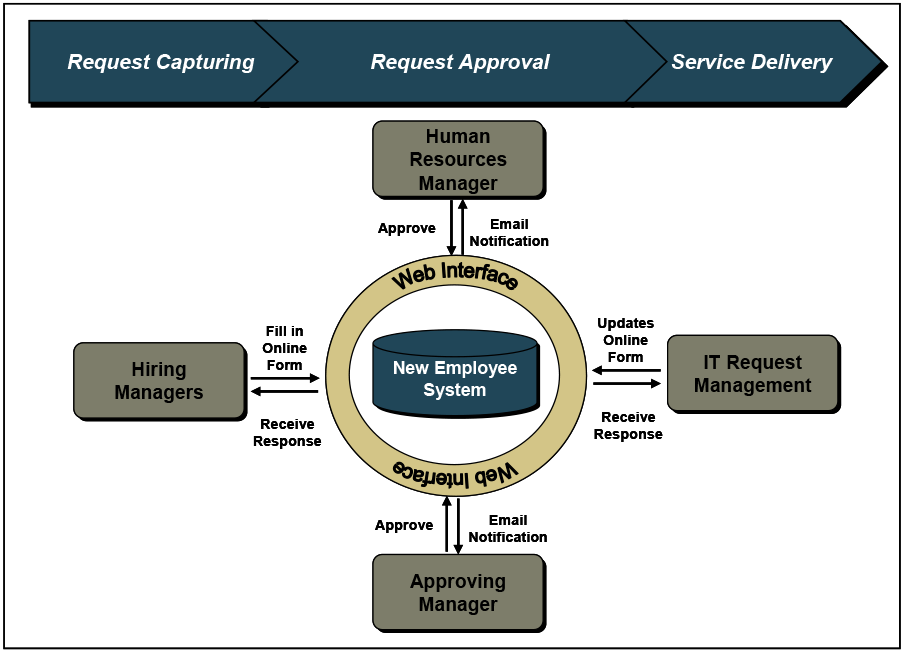

Solution Architecture

Feedback from the business over the years had shown a growing frustration with setting up the IT environment for new employees, which included access to a PC, corporate applications, internet access etc. Most companies will have a similar process in place, which could be labelled: “The New Employee Process”. Despite its critical nature and high visibility throughout the business, reliable process information was not available:

- No written process documentation was available, which would provide an end-to-end overview on process steps, when to involve external service providers etc.

- No performance requirements/SLA requirements or actual performance numbers could be obtained

- The vast majority of process steps were performed manually and relied on paper-based input

Six Sigma’s DMAIC was chosen as the underlying approach to analyse and improve the customer experience, in particular as there were conflicting opinions and views about the causes of the problem. However, no reliable data was available on the overall process performance, as such manual data had to be collected which limited the ability to conduct detailed root cause analysis. The analysis performed to determine the root causes for the inefficiencies included some basic statistical analysis, but to a much larger extent focused Lean value stream mapping to document the process and identify any form of waste it contained.

The 20-week project achieved a significantly increased productivity for new starters in the organisation, with a total productivity gain of 750,000 A$ p.a.